To produce the best results in a powder coating project, the supplier must follow steps to ensure quality. The following is an overview of areas to consider during a powder coating project.

Preparation

First, clean your metal of oil, rust, scale, weld splatter, or weld flux. Without thorough cleaning of any defects, the coating will eventually flake off.

To ensure a durable finish, etch or blast your part to ensure a surface that helps the powder coating adhere to the metal. While preparing the metal surface, you can add extra rust-preventative treatment to enhance durability.

Consistency

Use only clean, dry air at a consistent pressure to avoid spraying powder at varying air pressures. This application will produce uneven and unpredictable results. Check for moisture in the air lines, which can cause issues in the powder application.

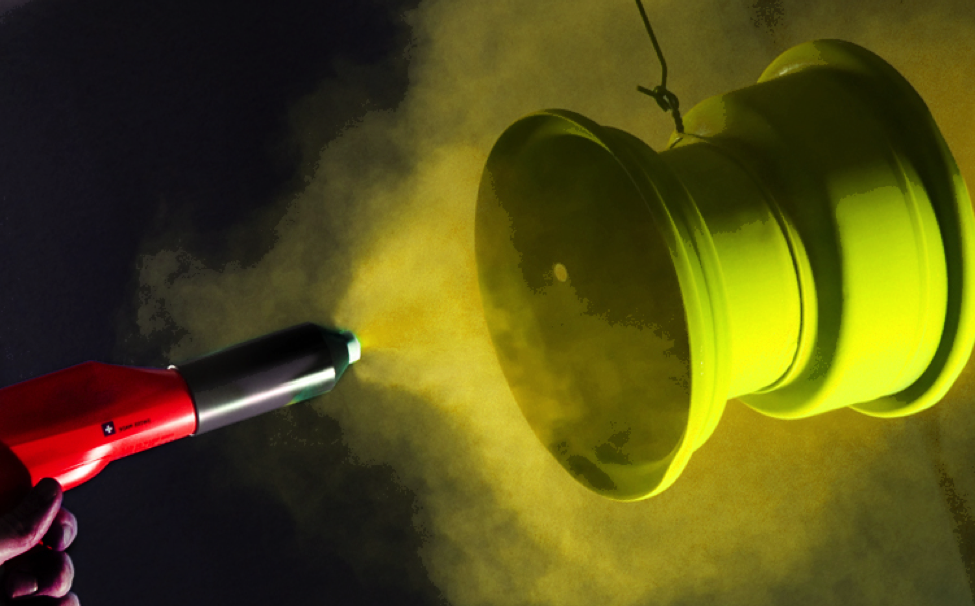

Make sure the gun is set correctly for the part and the powder being sprayed. A professional quality gun will have standard presets and presets that can be used for custom settings to apply the powder properly.

Spray your powder consistently using a cross-coat pattern. Generally, three passes are the standard application, but two or four may be needed depending on the powder setting and the speed of the sprayer.

Quality Control

After application, be sure to check your work before baking. It is quicker, easier, and less costly to fix a defect before rather than after the powder is cured. Inspect all surfaces for uniform powder coverage and powder build-up.

Use the correct cure temp and time according to the powder supplier’s datasheet and curing schedules. If not mentioned in the supplier information, add the time it takes for your parts to reach the proper curing temperature.

A solvent rub test is an excellent way to check that your parts are cured. It is helpful to document defects to have a record of defects. This data will help you identify the causes of any problems to help you avoid them on future projects.

Since opening its doors in 2000, Enviro Tech Coatings has been laser-focused on delivering metal finishing, painting, and coating services far exceeding industry standards. We maintain Air Permits and are a fully approved site for blasting and painting. If you would like a bid on a project, please get in touch with us at 989-495-0000 or visit enviro-tech-coatings.com.